Lessons in battery design learned from Boeing 787 battery failures

In 2013, a Lithium-ion battery fire was discovered on a parked JAL airlines plane. After this, at-least 2 more planes which had similar failures which led to the grounding of the Boeing 787 Dreamliner until this issue was resolved.

Boeing had contracted out the battery manufacturer for this plane to GS Yuasa, a Japanese battery manufacturer.

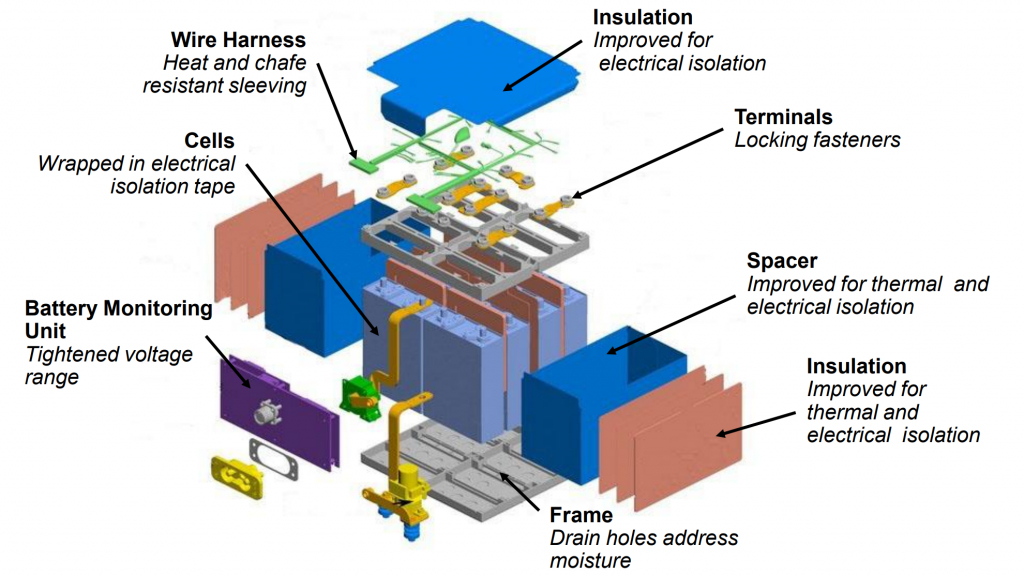

Before we proceed with the failure analysis, take a close look at this picture and note down any potential issues you can spot with its design. This will help you in retaining the learning which we will be discussing from the failure analysis.

Here is a short list that we came up with -

- Cells are spaced too close to each other

- Outer body of casing does not have proper venting

- Can't see torque markers on the bus bar to battery terminal screws

- BMS is in the same compartment as the cells, so if an edge cell goes into thermal runaway, it can potentially stop the BMS from functioning properly within seconds.

Let's now understand the usage of these batteries on the 787 Dreamliner.

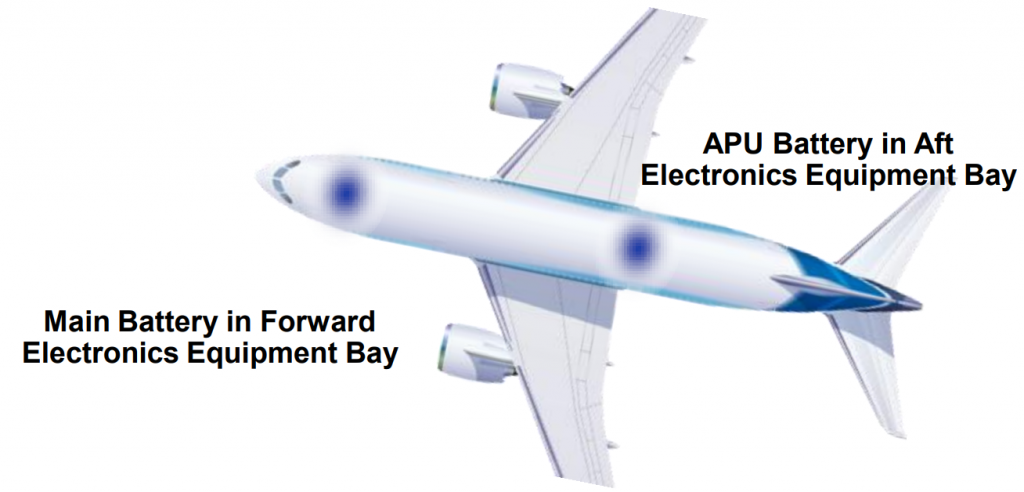

There are 2 Lithium-ion battery units available on the Boeing 787 dreamliner. The MBU (Main Battery Unit) and the APU (Auxiliary Power Unit).

The MBU is responsible for the following functions:

- Refueling

- Brake power while towing

- Navigation lights while towing

- Backup power in the case of generator failure

The APU is responsible for the following functions:

- APU provides ground power and serves as backup power in flight.

Lets now proceed with the failure analysis of the MBU in the Boeing Dreamliner. Here is what the Battery looked like, after the thermal event.

Based on the picture and the following investigation, a single cell internal failure caused it to vent using the inherent designed safety value. However, instead of it being an isolated cell fault, the heat and pressure released from the single cell failure propagated to surrounding cells causing them to vent as well. This caused the MBU to fail.

Here is a short video clip of MakerMax Director, Akshay Gill explaining thermal runaway in batteries. There is a lot of lessons that can be taken from the failure analysis of events like the Boeing 737 Dreamliner battery failure to incorporate these fixes to Battery design in Electric Vehicles as well.

The Boeing engineers took corrective measures on the battery issues in the following ways

- The Battery Monitoring Unit overvoltage levels were reduced to prevent overcharge

- The Battery Monitoring Unit undervoltage levels were increased to prevent deep discharge

- Cell spacing was improved to reduce the chances of cell to cell thermal event propagation

- Dielectric insulation was added between the chassis and the cells for improved thermal and electric isolation

- The BMU unit was isolated from the cell chamber

- The wires connecting cells were given heat and chafe resistant sleeving to reduce the cell to cell propogation

- Self locking screws were added to the cell to bus bar connections to make sure they are not over-torqued

- The MBU was enclosed in a stainless steel enclosure as a third level of safety. The key part of this enclosure is that it stops a fire from igniting inside it and appropriate venting is provided, which allows pressure equalisation in case of a cell venting scenario.

Apart from improvements to the MBU, there were changes made to the on-board charger unit as well. GS Yuasa, the Battery manufacturer also improved their cell level testing which included cell cycling simulations and cell ageing profiling using equipment similar to the MakerMax CCAX4.

The lessons from this failure and other such recent events are important to consider and build into your Battery design and QA processes for Electric Vehicles.

Battery safety is a growing concern as we see more energy dense Lithium-ion batteries being used in automobiles, aerospace, defence, stationary storage and portable electronics. We've encapsulated lessons from such recent failures in the form of a course to assist manufacturers in strengthening their internal Battery design and QA processes to ensure safety of devices, vehicles and consumers. Check out this course below to learn more.

Get started with our free 10 day course on batteries delivered straight to your email inbox!